Last month, DJI released its new consumer drones, the Mavic 2 Pro and the Mavic 2 Zoom, which were probably the most advanced drones the company has ever released. The Mavic 2 Pro features the Hasselblad L1D-20c camera, which can capture iconic image quality. It can stay airborne for up to 31 minutes at a speed of 72km/h. Today, I’ll show the teardown process of the DJI Mavic 2 Pro.

This is the picture of the Mavic 2 Pro (on the right) and the Mavic Pro (on the left). Do you know why I want to tear down the Mavic 2 Pro? The Mavic 2 Pro has upgraded some hardware. This drone boasts six visual sensors, while the Mavic Pro features four; it sports the 4S battery, and the latter sports the 3S battery. Besides, its CMOS sensor has an active sensing area that is four times more effective than the original Mavic Pro. Compared with the Mavic Pro, the Mavic 2 Pro’s size is slightly bigger. First of all, start from the bottom.

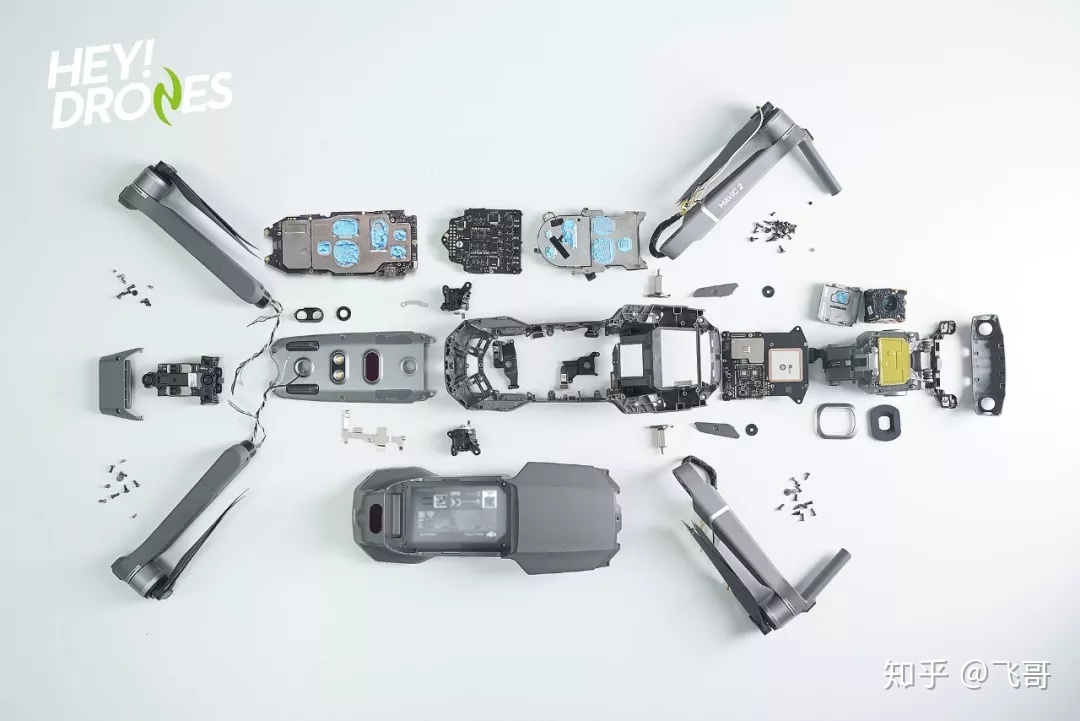

The screws at the bottom are small, and they are installed tightly. After taking out eight screws, remove the cover. We can see its internal structure is compact and complex, from which we can infer that this drone is difficult to tear down. Lots of screws need to be removed. The wireless connector is on the back. And screws are behind the connector. Its internal structure is well fixed by screws. Then, take out another eight screws. After removing the chip on the top, a large circuit board is found below it. This large board is composed of two circuit boards in a tight layout.

To avoid making the drone out of work, I didn’t remove the cover of the chip module. The cooling fan looks exquisite. It is placed above the chip module. Next, I will remove its camera and visual sensors. There are many screws waiting for me to remove. We can notice that this drone’s footage has a different design. The whole footage and shock ball have been embedded into the top, which is firmer and space-saving. And only in this way can it carry the Hasselblad L1D-20c camera.

I have to remove the top cover violently since the top cover is tightly fixed. I finally removed the top cover, though it’s not easy. However, a more serious problem comes. A soldering iron is needed for further teardown. The GPS module is placed on the top. This design not only allows the module to receive the signal better but also reduces the influence of other electronic components on the GPS signal. The IMU is connected to the shock ball, which can prevent the IMU from disturbing blade resonance.

This is the small visual sensing module at the tail. A set of binocular cameras, two monocular cameras, and a set of infrared TOF transmitters and receivers are integrated into such a small module. By the way, only three camera lenses have been integrated into the camera module that the Huawei P20 Pro features. In fact, a camera lens always comes with a CMOS and an ISP. This is the Hasselblad L1D-20c camera. The extremely small footage carries a 1-inch CMOS camera. There is no screw found in the footage.

As it is rumored that glue has been applied to the footage, I tried to open it with a screwdriver but failed. It is amazing to see a COMS camera in such a small size. I was impatient to learn its internal structure but ceased to disassemble it further because it would damage its internal structure. Until now, the disassembly of its camera has been finished.

I removed the PMU with the soldering iron. Then, I removed the front axis. According to the Mavic Pro engineer, this axis can be folded over 5000 times. After disassembly, I believe what the engineer said about the axis’ foldability. Besides, its rear axis is also of good durability.

The appearance of this drone has not changed much. However, as it becomes bigger, heavier, and more powerful, its internal design should be more compact and complicated. I spent three hours finishing the teardown of the DJI Mavic 2 Pro.