The Meizu Pro 7/Pro 7 Plus has been launched officially. The phones have an all-new rear screen design and an all-new interactive mode on the back. Adding the rear screen requires the phone to hold two screens (in the meantime, keeping the phone body’s thin thickness) and a large battery. How to achieve this? Today, we will disassemble the Meizu Pro 7 Plus to explore its internal structure.

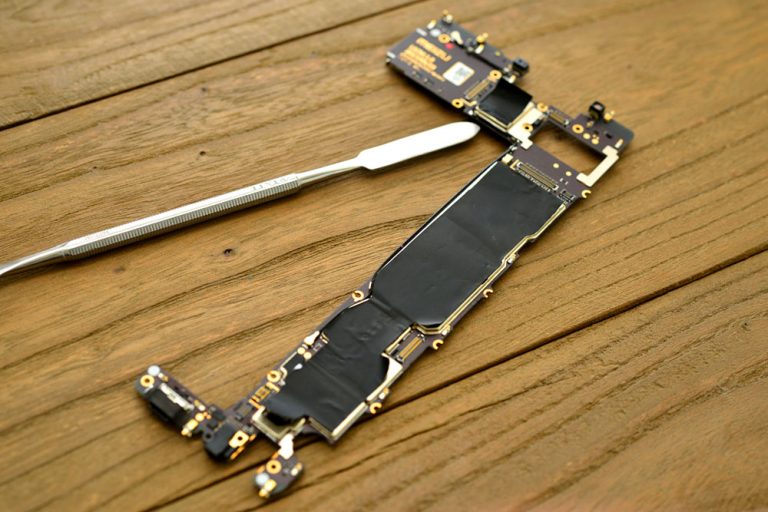

The teardown of the Meizu Pro 7 Plus first requires removing the two screws which are beside the USB port. The screw, which is the same screw that iPhone adopts, has the screw specification that most phones currently use.

After removing the screws, we can disconnect the phone’s screen with a buckle. The phone is connected to the fuselage through a clip.

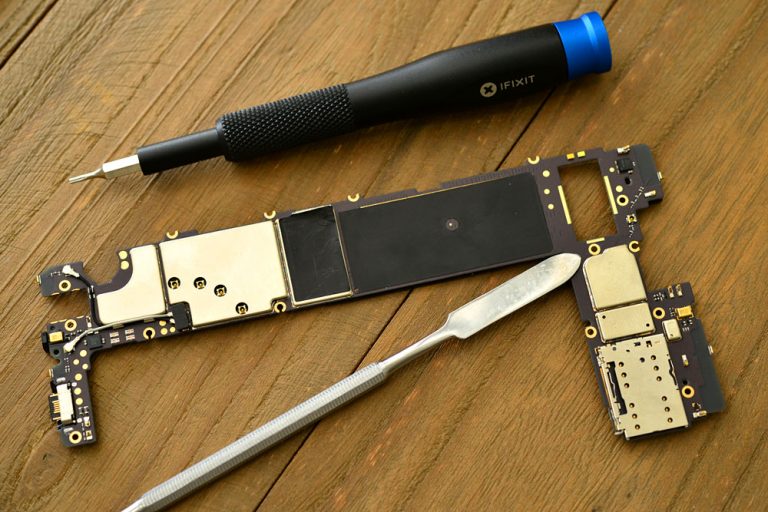

Taking the main screen apart, we can see that the screen is connected to the motherboard through a ribbon wire. The main screen is glued to the middle bezel. The motherboard is directly installed on the phone’s back case, which is a different design compared with Meizu’s previous phone’s design. The motherboard is installed in the middle bezel. Such a design is to consider the installation of the rear screen.

The phone features a main Super AMOLED screen that is easy to control. The rear screen also adopts the AMOLED screen. Although the phone has two screens installed, it remains thin.

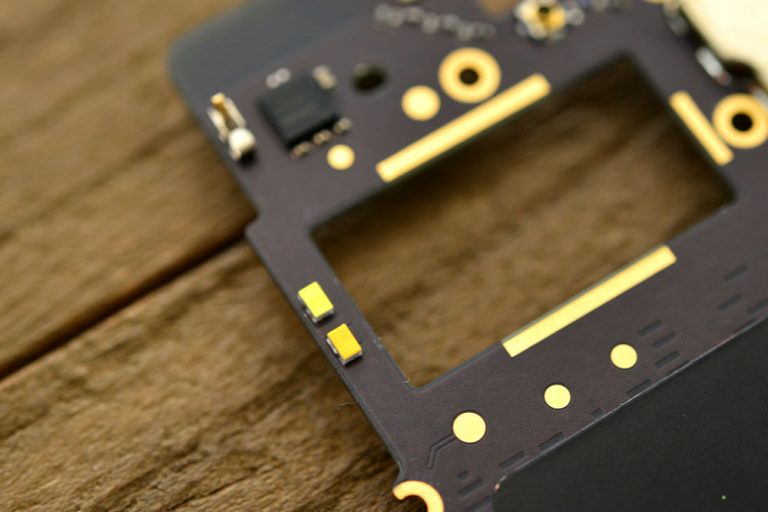

The phone’s front plate has installed a loudspeaker, and it has saved ports for the front camera, infrared sensors, and distance sensors.

The phone’s front plate has installed a loudspeaker, and it has saved ports for the front camera, infrared sensors, and distance sensors.

It adopts an L-shaped motherboard instead of the three-stage design because the phone’s rear screen has occupied part of the battery’s space. If the phone adopts a three-stage design, its design and manufacturing costs will be greatly improved.

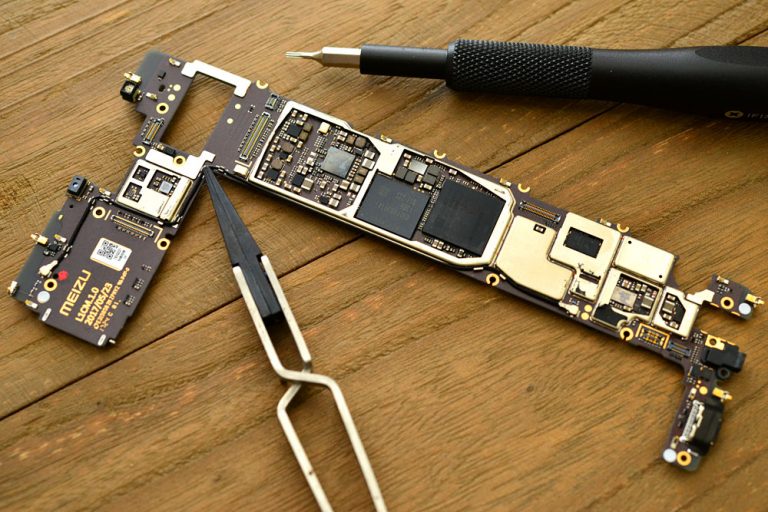

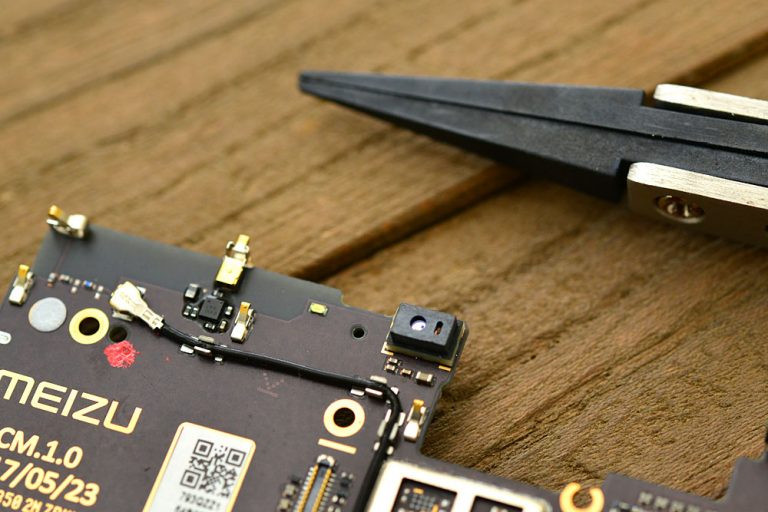

We can notice that Meizu’s logo is on the PCB, which shows the date and PCB version. The Meizu Pro 7 Plus PCB is made by a large-scale PCB manufacturer that has made many flagship products.

We can notice that Meizu’s logo is on the PCB, which shows the date and PCB version. The Meizu Pro 7 Plus PCB is made by a large-scale PCB manufacturer that has made many flagship products.

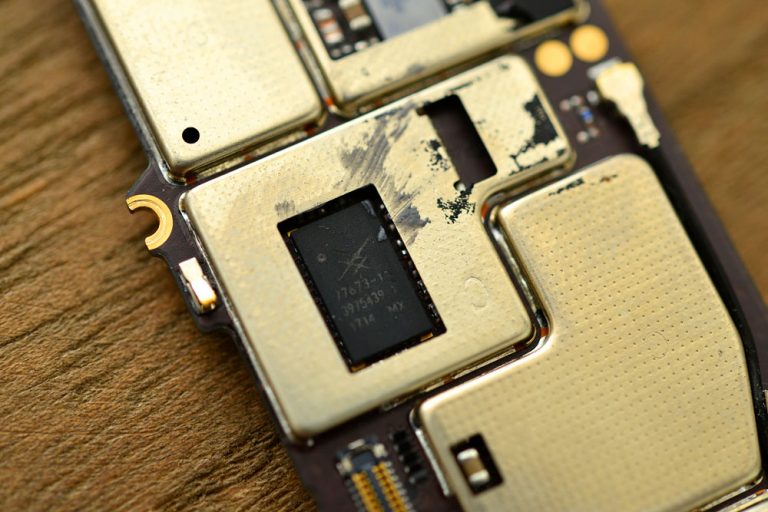

The Meizu Pro 7 Plus’s PCB shield case is covered by black graphite conductive paste. Uncover the paste, and the chip will be spotted. The graphite conductive paste supports not only heat dissipation but also shielding action.

PCB’s shielding case on the Pro 7 Plus is covered by a graphite heat-conducting sticker.

Removing PCB and the back case of the phone can be seen.

The phone sports a 3,500mAh battery and adopts mCharge 4.0 QC technology, which supports 5V 5A for faster charging.

The phone sports a 3,500mAh battery and adopts mCharge 4.0 QC technology, which supports 5V 5A for faster charging.

The Meizu Pro 7 Plus adopts a CNC process on its back case to install the rear screen.

It uses the mosaic technique to install the rear screen in the back case, which has a very high installation requirement. The rear screen is totally embedded into the back case and can’t be removed.

The whole screen’s layout design is quite sophisticated, which requires a high-level process. Meizu has invested a lot in the design of the rear screen.

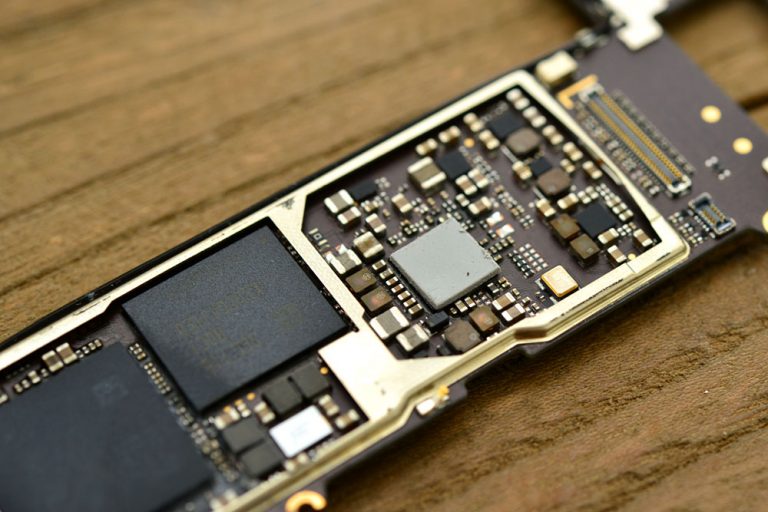

Uncover PCB’s graphite heat-conducting film and a variety of chips on the motherboard can be spotted. The Meizu Pro 7 Plus’ main chips are placed on the PCB’s front.

Some chips have heat-conducting posts, which can effectively take the heat generated by the chip away.

Some chips have heat-conducting posts, which can effectively take the heat generated by the chip away.

The PCB’s infrared sensor is used to sense the distance between the phone and the user’s face while the user is answering the phone.

The light sensor is on the other side. It is used to control the screen’s brightness by sensing the light.

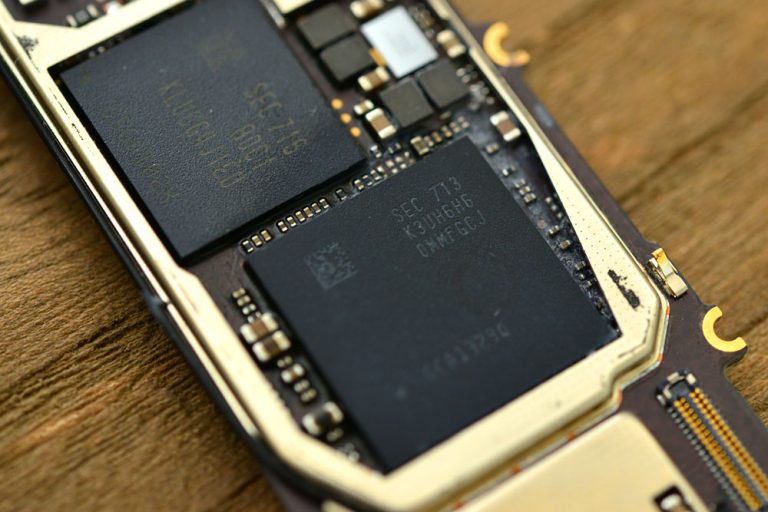

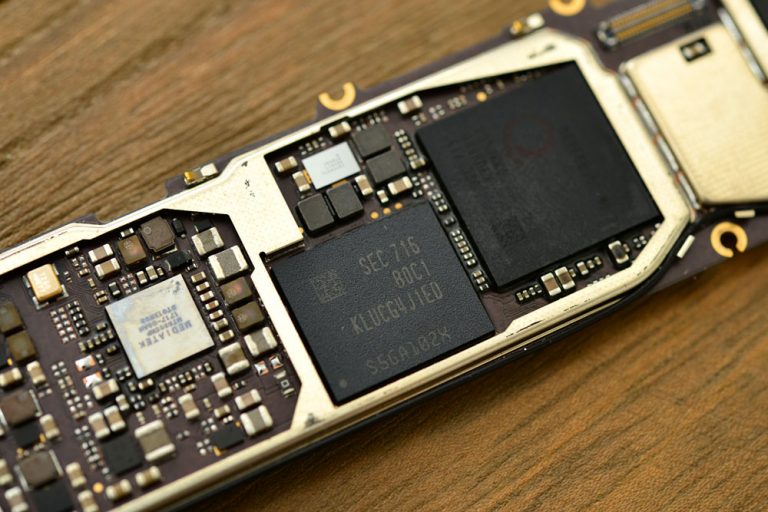

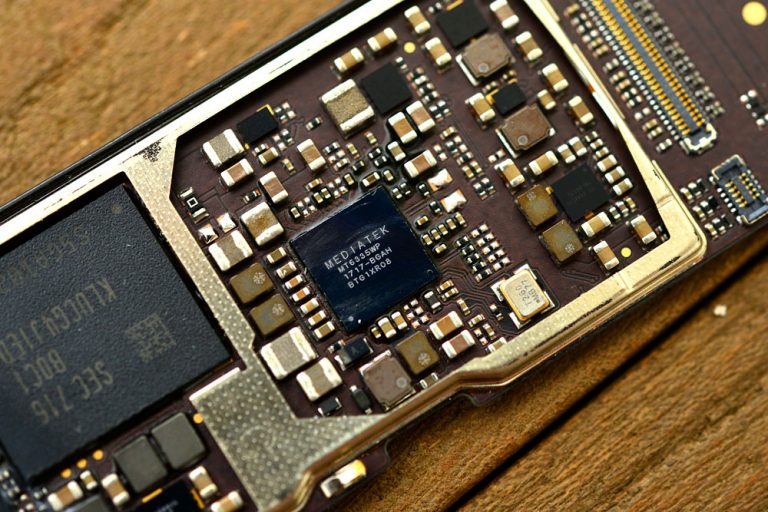

The Meizu Pro 7 Plus uses LPDDR4X storage and comes with 6GB of RAM. Its memory chip and CPU adopt a double-layer seal to save PCB space. The Meizu Pro 7 Plus is powered by MediaTek’s deca-core Helio X30 processor. The processor has two ARM Cortex-A73 cores, four ARM Cortex-A53 cores, and four ARM Cortex-A35 cores. It uses a 10nm process, which has good performance and lower power consumption.

The Meizu Pro 7 Plus uses Samsung’s UFS storage chip and comes with 64GB of ROM. UFS storage chip brings faster read-write speed.

SKYWORKS 77673, which is all networks’ signal amplifier, is used to send and receive signals.

MT6336WP, which is a power management chip, can work together with Helio X30.

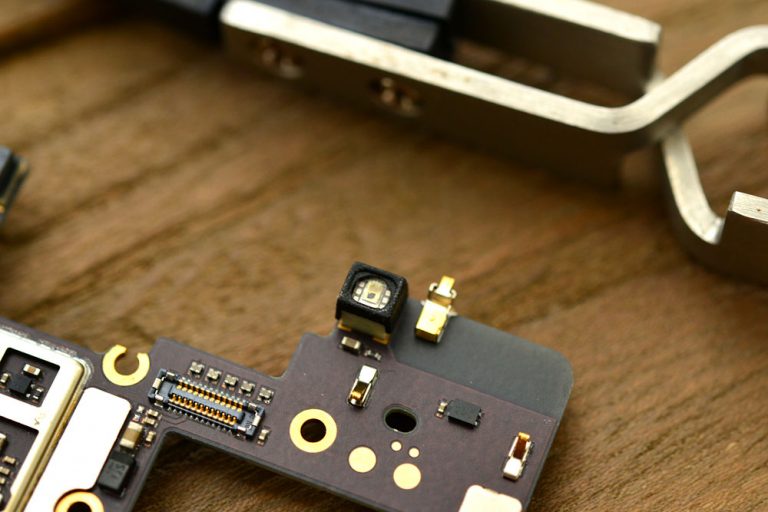

The double-color LED is on the PCB’s back.

The Meizu Pro 7 Plus features a dual camera setup with 12MP (colorful) and 12MP (black and white) sensors sealed together to avoid image formation problems during installation. It also features a 16MP front camera.

The Meizu Pro 7 Plus has adopted an all-new design on its internal structure to add a rear screen. It adopts an L-shaped PCB and has an optimized design on the back case, which makes the installation of the rear screen more refined.

The Meizu Pro 7 Plus features AMOLED screens on both the main and rear screens, which gives you good control over the thickness of the phone. It uses high-quality materials and components. Compared to Meizu’s previous phones, the teardown process is more difficult because it employs a more complex process.